Close

Electrical Command and Control Panels

Electrical Distribution Panels

Machine Panels

Refurbishing Plant

Adaptation of Electrical Panels for Energy Saving

Creation of Prototypes

Electrical Systems APIT specializes in designing and implementing electrical command and control panels, distribution panels, and machine panels. This includes energy-saving adaptations and prototype creation for custom solutions.

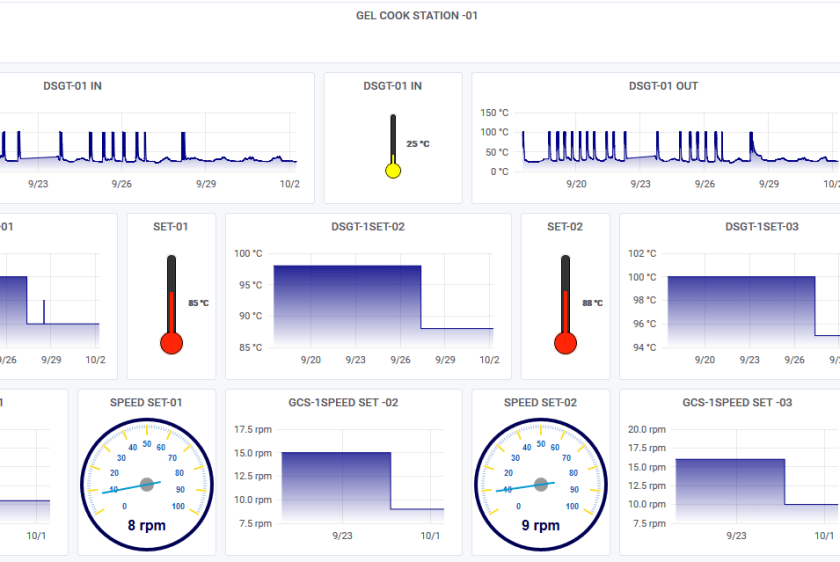

APIT offers end-to-end process automation and plant-based automation solutions, leveraging IIoT technologies for real-time data capturing and remote visualization of entire processes.

APIT supplies a wide range of machinery for paddy milling, dal milling, storage, cleaning, and conveying systems. This includes silos, bins, pre-cleaners, aspirators, destoners, and a variety of conveyors and elevators, all designed for optimal performance in agricultural processing facilities.

IIoT Integration APIT’s IIoT solutions facilitate live data capturing, remote process visualization, and enhanced efficiency through real-time monitoring, predictive maintenance, and automated reporting systems.

APIT’s PROSE is a unique system that integrates plant machinery, instruments and products into one system. This means that with PROSE, it is possible to access the process data for all the processes that are required to control the fortification bioprocess of bran and starch remotely via an iPad or a mobile app.

APIT provides the food and agriculture industry with fully-automated Parboiling and Drying units along with the PROSE software that allows easy monitoring of the process from afar through online applications controlled by PLC. Every process parameter is monitored online and any error can be rectified there itself.

Hydration time and temperature combination plays a crucial role in the colour of the paddy. For a darker colour, the hydration time is less and the temperature is more. For a lighter colour, the hydration time is more and temperature is less

To compete in today’s market, manufacturers need improved quality, faster cycle times, and increased visibility and flexibility, all while meeting regulatory compliance. That’s why APIT manufacturing technology solutions enable manufacturers to see more, know more and do more to become more agile, optimise plant floor performance and embrace market changes. Data that is generated by the plant of increasing importance. On an IoT platform, Data Analytics plays a major role in making critical decisions across the plant. Examples of this include identifying the plant’s OEE, traceability of the product and variations in process parameters resulting in reliable productivity.