Close

In batch-wise parboiling, paddy undergoes a hydrothermal treatment before milling.

Here’s how it works:

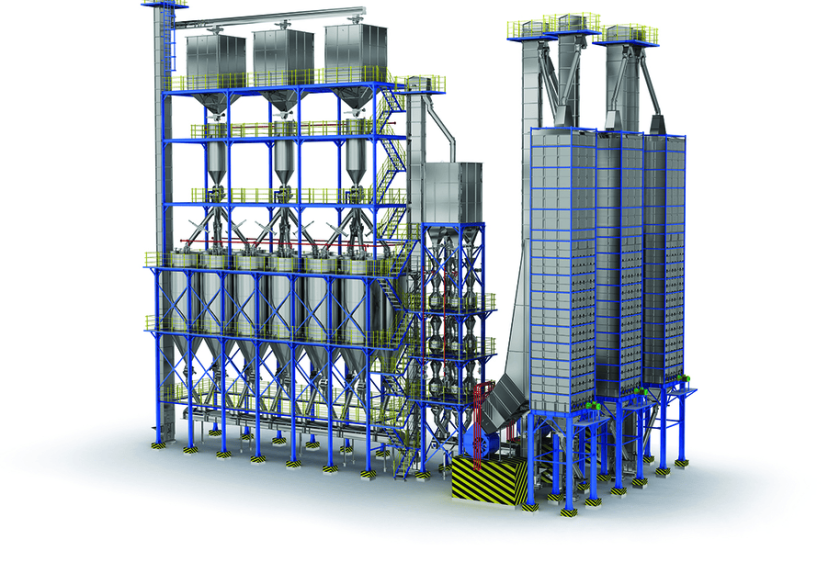

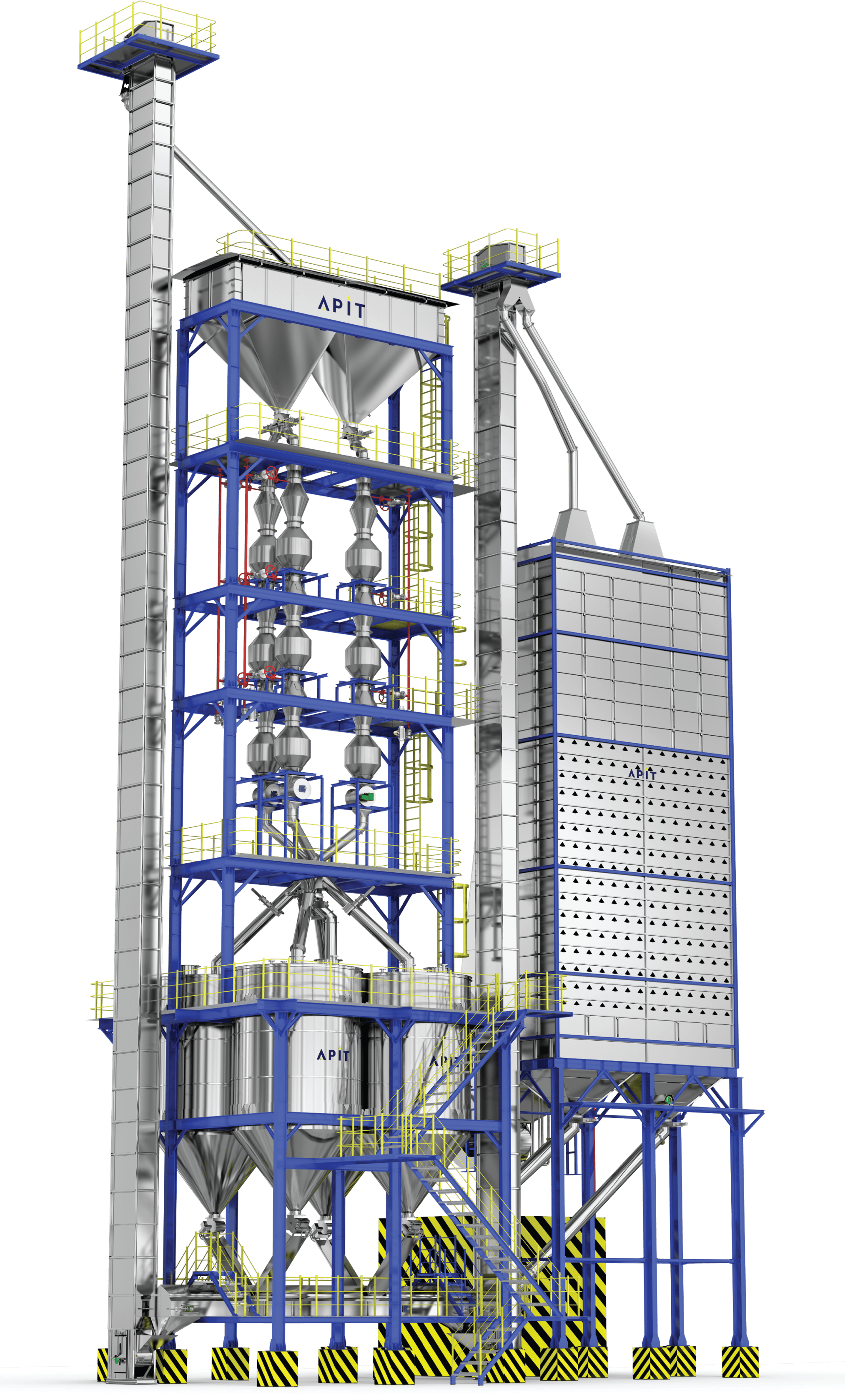

APIT’s patented innovative Super Ageing Technology offers a comprehensive portfolio of scientific process engineering system which transforms harvested or new paddy into nearly one-year old paddy. The process involves ageing of rice by thermal treatment and thermal seasoning (precise combination of steam and temperature) which ensures consistent quality and renders the rice with desired cooking qualities comparable to naturally aged rice / approximately one-year old rice.

APIT’s super ageing technology brings about uniform and high product quality which directly influences high-market value. This continuous & unique super ageing process with highly advances automation eliminates the grain-to-grain nonuniformity in comparison to other continuous process and the batch process systems.

Each paddy receives uniform steaming at a uniform rate by the involvement of the branched sparger system. Further, this system is intact with no moving parts or adjustments and is controlled by virtue of fully automatic sensors and valves for both paddy and steam. This reduces the human interference and brings about consistent and quality results of the output paddy. Natural ageing through conventional processes requires undesirably long storage duration, in addition to associated higher operational and maintenance costs.Alternatively, artificial ageing of rice by APIT achieves similar results in lesser time and lower cost. Proper hygiene process and nutrition preservation with least process broken, zero process rejection, maximum shelf life of rice. This process brings about higher cooking quality in terms of water uptake ratio, maximum volume expansion and higher elongation ratio, maximum fluffiness and retention of micro and macro nutrients of cooked rice.

Compared to conventional ageing, the APIT’s Super Ageing Technology is highly sophisticated and designed to maximize the process of producing uniform and quality consistent paddy 365 days and 24×7 in each batch employed.

APIT has a unique concept of advanced state of the art parboiling systems called the eco parboiling system which produces high quality of parboiled rice abstaining the soaking step. This process brings about 80% reduction in water consumption in comparison to the conventional processing. Additionally, APIT’s eco parboiling system ensures best rice with hygienic process, quality parameters, nutritional preservation, and environment friendly methodologies. The advanced eco parboiling system can produce the desired color of the parboiled rice based on the global consumer preferences.

APIT’s eco parboiling system has a scientifically process based infrastructure. The process will be carried out in multiple phases with following phases which includes,

Ageing of the harvested paddy followed by molecular hydration system with consumes 20% water. Further, this step is followed by pressure parboiling and resting. Lastly, the paddy is subjected to final gel cook and rested for a definite period of time for setting the desired color acquisition and subsequently subjected to milling.

Our eco parboiling process is driven by pre-designed process standards integrated with our patented parboiling design software PROSE. Thanks to the PROSE process design software which is applicable for most of the global rice varieties which considers of the critical parameters mainly the moisture, age and density of paddy.

Grain storage bins are the most cost-effective scientific solution to store grain for a short to medium duration. Some grain storage bins are used to store grains for long term duration also,

The main features of APIT grain storage bins include,

1. Ventilation systems to keep the grains safe inside the storage bin

2. Ventilation channels.

3. Double-wall rings, which insulates the interior from the external temperature.

5. Roof extractors to remove air from the interior of the storage bin.

APIT grain bins are one of the top grain storage systems within the industry. APIT grain bins offer the most reliable and customizable quality product with variable eave heights along with maximum grain- holding capacities to meet the required storage challenges by our customers.

The APIT grain bins also features innovative roof structures, body sheets, bin stiffeners, anchoring systems and accessories par with the industry standards.